Production Process

We have set up a reliable Environmental & Quality Management System.

And our safe and clean production facility guarantees 100,000 daily production capacity.

Full R&D through affiliated R&D center, strict quality control, and over 100,000 large production capacity across 3 factories in Yongin city spanning the area of nearly 6000㎡. We take care of production, packaging, release and distribution at one stop!

| Facility | No. | Daily Production Capacity (8 hours) | Monthly Production Capacity (22 days / 8 hours) | Remarks |

|---|---|---|---|---|

| Steam Agitator (3000kg) | 1 | Production up to 60,000kg 100,000 ea |

Production up to 1,320,000 kg 2,200,000 ea |

Processed kettle for broth and sauce |

| Steam Agitator (1500kg) | 3 | |||

| Steam Agitator (700kg) | 1 | |||

| Square Agitator (500kg) | 2 | |||

| Fire Grill Cooker (300kg) | 1 | |||

| Automatic Replenishment System (Conveyor, Recharger, Sealing) |

5 | Standard size (500g), 15,000 ea | Standard size (500g), 330,000 ea | For broth and sauce onl |

| Container Packager | 1 | 10,000 ea | 200,000 ea | |

| Seafood Packager | 1 | 15,000 ea | 300,000 ea | |

| Automatic Circulation Cooling System (No. 1-3) | 720HP | 15,840HP | Broth and sauce freezing below 10℃ |

|

| Quick Freezer | 100,000 ea | 2,200,000 ea | Instant freezing | |

| Aluminum Scanner | 1 | Metal detection of aluminum metalized package container (except for aluminum container) |

Iron 2.5mm / SUS 3mm detected | |

| Metal Detector (No. 1-5) | 5 | Highly sensitive detection of iron and metal | Iron 1.5mm / SUS 3.5mm detected | |

| HVAC System and Floating Germ Control System | Maintain 15 ℃ in production processing room and the control system for air-floating germs |

|||

Good food starts from good base. We are making top-quality food by applying strict quality control standards we made added to HACCP.

-

01

Product Development

-

02

Incoming & Inspection

-

03

Pre-Treatment Processing

-

04

Line Processing

-

05

Metal Detector Screening

-

06

Quality Control

-

07

Packaging

-

08

Shipment

TaejongFD have strict personal hygiene control rules, making food processing employees to cover their hair, mouth and feet and to go through hand disinfector and air shower to stop any kind of germs.

Furthermore, workers are required to wear apron and arm cover in order to enter the working zone.

-

01

Keep personal hygiene practices Wear uniform, hat,

mask and indoor boots -

02

Use hand disinfector

-

03

Go through air shower

-

04

Wear apron and arm cover

Certification

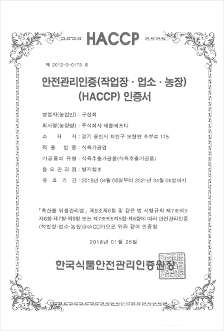

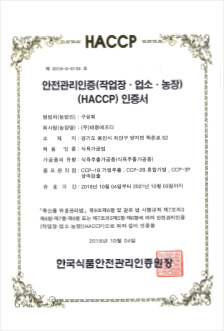

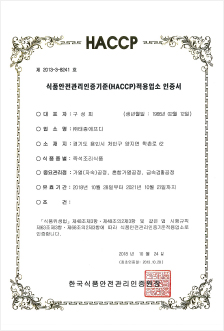

Sanitation is the very first step of manufacturing and making first impression with customers.

HACCP certification is operated with quality and environment

When making food, we recognize the importance of making process right to create the taste we want to deliver. We are producing immaculate food products from credible production facility. Experience chef in the kitchen within your easy reach.

-

HACCP Certified (Yongin) Meat Extracton

-

HACCP Certified (Yangji) Meat Extracton

-

HACCP Certified (Yangji) Instant Cooking

-

Innovatively Managed Small Enterprise Certification

-

Quality Management System ((ISO9001)

-

Quality Management System (ISO14001)

-

Innovatively Managed Small Enterprise Certification

-

Accredition of Affiliated R&D Center

Award History

We are living up to the values of integrity, honesty and socially responsible.

TaejongFD will commit itself to be a credible company you can always rely on.

-

Selected as good job creation company

-

Selected as excellent good job creation company

-

Diligent tax payment verification

-

Minister Award of SMEs and Startups